what are you looking for?

Air compressor is "electricity-eating tigers" in commercial power,power consumption occupy 20%,but it is necessary equipment in enterprise.How to use the same electricity,to create more air,and realize energy conservation,we try hard and study it,now obtain important breakthrough.Under original work efficiency,Huada permanent magnetic frequency conversion screw air compressor save 35% energy for user.

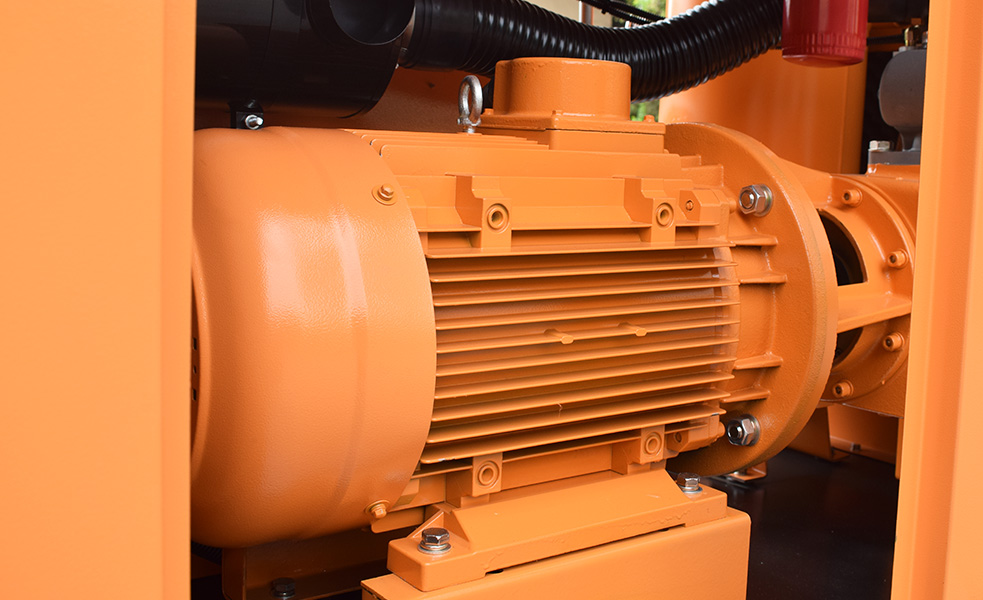

Huada permanent magnet screw air compressor uses high-strength NdFeB(neodymium iron boron) magnetic steel,high magnetic energy product and coercivity of NdFeB magnetic steel,make rare-earth permanent magnet motor have small size,light weight,high efficient,good character etc., a series of advantages.

Huada permanent magnet screw air compressor reduces energy consumption through the following points.

1.The permanent magnet motor and the host adopt a split and direct connection structure,and the motor adopts an IP54 protection level,which has low temperature rise and high efficiency.

2.Eliminate inefficient conversion process from full load to unload,avoid unload power consumption.

3.The microcomputer synchronization control system controls the fan speed according to the exhaust temperature to suppress current waste.

4.Cooling fan frequency conversion control,energy saving about 5%.

5.Provide free choice of pressure from 4 to 13bar,which can minimize energy consumption.

6.The efficiency of permanent magnet motors is more than 20% higher than that of ordinary motors when working at low speeds.

7.The frequency conversion range is from 25% to 100%. The greater the fluctuation of the system gas consumption, the more obvious the energy-saving effect.